The market for dual systems – still the core business of the Der Grüne Punkt group – remains shaped by intense competition. During the reporting period, our company continued to devote a great deal of time and energy to ensuring fair competition conditions for the benefit of our customers, even though the full effects of new German Packaging Act have yet to emerge. Our goal is still to make major strides in profitability in what is an extremely challenging market. Our management team is taking a holistic approach: While we are investing a great deal of effort in further developing markets, the group is working simultaneously to make cost structures more efficient – for instance by improving relationships with our suppliers (e.g., constantly modifying contract terms for operators of sorting plants for lightweight packaging). A uniform management system that combines quality, environmental, and energy measures makes us even more efficient. A few structures (e.g., data collection processes) have been standardized across the company. Particular attention is being paid to the interface between manufacturing and our main site. A few processes still have to be optimized since three different companies of varying natures inherently have diverse customer-supplier relationships. The goal remains to introduce an integrated management system for all locations.

Boom in recycled plastic expected

The industry is under mounting pressure to embrace sustainable solutions for plastic in packaging and other products. But this has yet to trickle down to the market for recycled plastic. As a result, this division has not delivered satisfactory performance levels to date. A turnaround is just around the corner, though, as demand for high-quality recycled plastic is set to grow. In the light of this situation, our group of companies has made preparations so that we can meet this demand. In 2018 alone, we invested €3.7 million in maintaining and increasing capacity at the two plants run by Systec Plastics Eisfeld and Systec Plastics in Hörstel. Investments in the region of €10 million are slated for 2019.

Award-winning applications

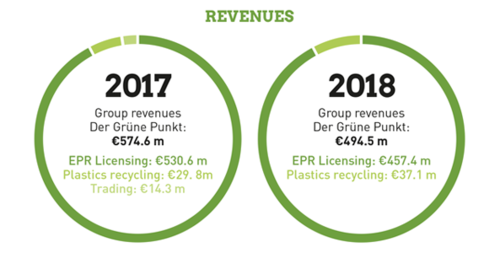

The Recyclat-Initiative, which was founded by Werner & Mertz GmbH in 2012, walked away with another German Packaging Award in 2017. The partners succeeded in making flip-top caps out of 100 percent recycled polypropylene (rPP). These caps are used in packaging including for Frosch lemon cleaning products. Der Grüne Punkt delivered the recycled plastic – Systalen PRIMUS PP. The manufacturer COMPO also uses HDPE bottles made out of 90 percent Systalen. Its new hexagonal premium packaging for liquid fertilizer was recognized with a German Packaging Award in the sustainability category in 2018. It is another great example of closing the loop – making new packaging out of post-consumer packaging. We launched RAL-Gütegemeinschaft Rezyklate aus haushaltsnahen Wertstoffsammlungen e.V. to make recycled materials traceable and allow them to be clearly marked on packaging. A quality mark certifies that the product uses recycled materials from close-to-home collections of post-consumer sales packaging. While a boom is just around the corner in the recycled material market, revenues from our core business – participation of sales packaging in the Dual System – are falling because major customers.

FLAGSHIP PROJECT:

Keeping Toilets fresh – A new life for lightweight packaging

Everyone has seen them before: PET trays that protect tomatoes and herbs. Now they will get a second, third, or even fourth life – as containers to hold toilet freshener balls. There didn’t used to be a way to recycle PET trays. Werner & Mertz and Der Grüne Punkt worked together closely on developing a solution. The best thing? These little containers can then be fully recycled – so that one toilet after another can theoretically become nice and fresh (tray-to-tray recycling).

Rising quantities in the system, falling market share

However, this trend was accompanied by an increase in the quantity of packaging participating in the system as a whole. This figure grew from 1.558 million tons of lightweight packaging in 2016 to 1.728 million tons in 2018. This growth can be traced back to stricter rules contained in the German Packaging Ordinance, which applied into 2018, and updated Clearing Center contracts between systems, which were chiefly pushed forward by Der Grüne Punkt (read more in the Market section). We also felt the effects of our competitor ELS Systeme GmbH going bankrupt at the start of 2018, a blow that remaining system operators had to absorb. ELS was unable to service its debts to municipalities and, in particular, to waste management companies contracted with collecting lightweight packaging and glass. Additionally, ELS could no longer provide extra registrations tied to it underreporting the quantities participating in its system in previous years. The financial damage of an estimated €80 million also had a negative impact on Der Grüne Punkt’s balance sheets. This turn of events also required that we take further actions to optimize cost structures. These actions included adjustments to staffing costs (see the Social Issues section), intense digitalization of work processes through the SharePoint platform that we introduced in 2016, and the customer relations management (CRM) system that covered all of the group’s departments by the end of 2018. Manufacturers with small quantities of sales packaging can also ensure that their packaging participates in the system in a quick and legally watertight manner using the online www.verpackgo.de platform. The new ZSVR and its LUCID database, with which obligated manufacturers must register, are also having an impact. Several hundred thousand customers will likely also have to take part in the system. Making this happen in an efficient and customer-friendly manner was one of the biggest tasks and opportunities of 2018. Besides increasing online communications, we also expanded our phone hotline to cope with this challenge. A look to the future: Our move to a new building, which is scheduled to happen at the start of 2020, will further digitalize, streamline, and accelerate internal processes. Digitalized processes are not just quicker and more cost-efficient, but also better for the environment, as they save on resources like paper and energy-using areas.

Recyclables full of value

So what happens when our waste ends up in the bin? German consumers typically sort their packaging into three fractions: glass, paper, and lightweight packaging (aluminum, tinplate, plastic, and composites).

This infographic follows their path through a paper sorting plant, sorting plant for lightweight packaging, or glass processing facility. Different materials are sorted, cleaned, and recycled as best possible to create something new.

You can find an animated version by visiting www.gruener-punkt.de/whatbecomesofwhat