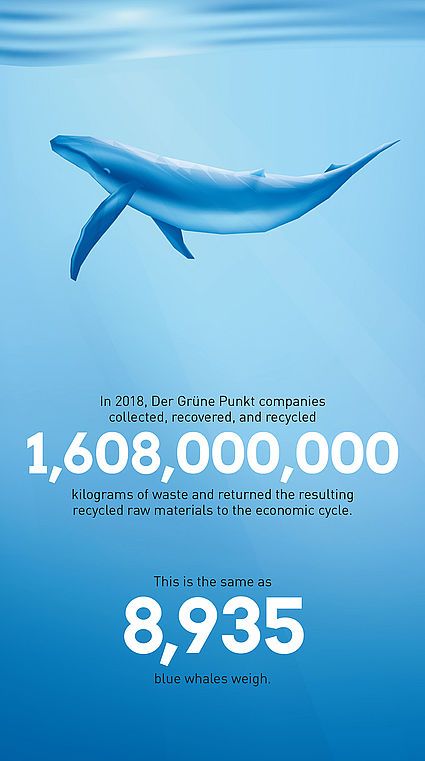

We want to start by mentioning an important aspect: the media repeatedly shows images of plastic waste being dumped in landfills, most recently in Malaysia. But the Dual System sells only very small amounts of plastic waste to Asia – and all of it is sorted plastic fractions rather than unsorted waste. We only send material to certified buyers that recover plastics using the latest technology and dispose of any residues properly. Let’s look at a few figures: In 2017, Der Grüne Punkt exported less than 2 percent of the waste plastics it sold to Asia. This figure fell to 0.15 percent in 2018, with more than 93 percent staying in Germany. Less than 7 percent was recovered in Europe (including Turkey and Ukraine). The majority of waste plastics exported from Germany to Asia therefore comes from commercial and industrial sources.

Well-planned investments

There is no doubt that collecting and recovering post-consumer sales packaging makes a substantial contribution to the global fight against climate change. We want to do even more by investing in new technology and modern processes. Our core business is circulating recyclable packaging materials in a closed loop. We aim to further reduce the environmental footprint in leading impact categories by optimizing processes, making all necessary logistics services more efficient, and investing in modern and energy-saving technology. We are well on the way: In 2017 and 2018, Der Grüne Punkt avoided a good two million tons of CO2-equivalent through recovery and recycling operations. Our annual life-cycle analysis is based on ISO standards 14040 and 14044 and is confirmed by experts from the Institute for Energy and Environmental Research (ifeu). The positive results demonstrate that anybody using recycled materials in place of virgin materials reduces harmful greenhouse gases. So using more recycled materials instead of virgin materials conserves primary resources, reduces CO2 emissions, and helps ease the strain on our climate. By advancing technical processes, we are improving the quality of our recycled materials and unlocking new demanding areas of application. One major issue is manufacturing odorless recycled materials. Ten workers are working on our own sensory panel to develop even better methods. They come from a wide variety of areas. One thing they have in common is that they have a sensitive nose. They regularly analyze new samples for our research department and document their results.

Recycled materials – a real alternative

Systec Plastics GmbH in Hörstel and Systec Plastics Eisfeld GmbH make premium Systalen recycled plastic for the international market. With this recycled plastic, we have developed a real environmentally friendly alternative to virgin plastic manufacturing that is used in injection molding, extrusion, thermoforming methods, and blow molding. More and more companies and municipalities are now using our recycled material as a high-quality solution in packaging, building construction, civil engineering, landscaping, transport engineering, and logistics.

Refreshingly sustainable

Werner & Mertz has achieved a world-first: for the first time, a body-care product is being sold in packaging made out of plastic from the yellow bag. Bottles containing Frosch Senses shower gel are made with 100 percent recycled HDPE. A special technical process developed together with Der Grüne Punkt and EREMA Group has made this possible. A human-toxicological report confirms the material’s safety. Another success is that the contents smell of orange blossom or pomegranate, for instance, but the shell is odor-neutral – a particular challenge when reusing waste plastic.

IN A NUTSHELL

Off the shelves and back again

This is how loops are closed: products made out of recycled plastic are now easy for consumers to identify thanks to the new RAL quality mark (see image). After all, Pro Carton found that 88 percent of German consumers want to know how environmentally friendly their packaging is. This strict quality mark proves that plastic comes from the yellow bag – and not from deposit-bearing bottles or industrial waste. The exact percentage is shown, either in German or English. At long last, the path taken by recycled raw materials is transparent. The new quality body RAL Quality Association for Recycled Material from Close-to- Home Collections, which was created at the initiative of Der Grüne Punkt, is focusing on providing complete evidence of its path. It currently has eight members: Systec Plastics Eisfeld and Systec Plastics Hörstel, Der Grüne Punkt, Werner & Mertz, Pöppelmann, Jokey Plastics, cedo, and Gizeh. And this number is growing.