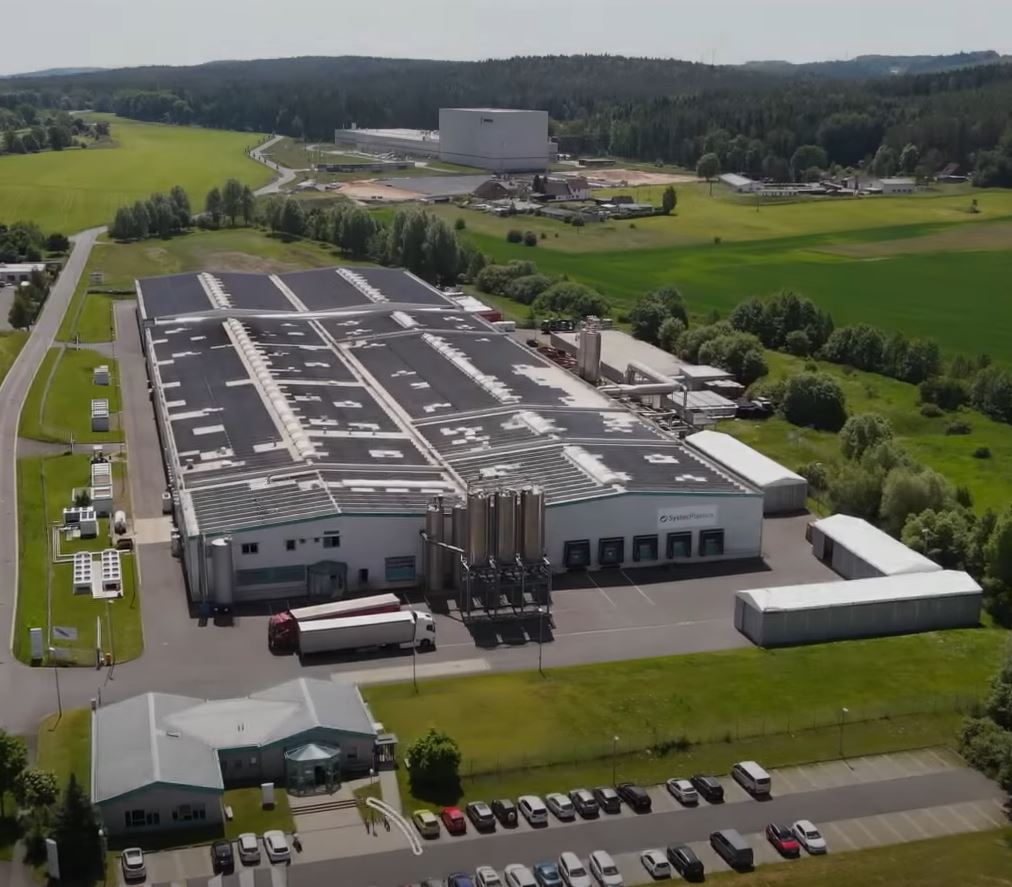

Eisfeld - the modern rFlex factory

Thanks to state-of-the-art plant technology and continuous innovations, Systec Plastics Eisfeld GmbH is the leading competence center for high-quality recycled pellets and compounds made of low density polyethylene (LDPE) with

- seven wash- and three extrusion lines

- one of Europe's largest exhaust air biofilter plants (filter size 1,000 m²)

- own test laboratory

Systec Plastics Eisfeld is one of the largest European producers of post consumer recyclates from yellow bags & yellow garbage cans. Currently, the annual output is approx. 28,000 t of rLDPE - with an upward trend due to extensive expansions from 2023 onwards.

Systec Plastics Eisfeld GmbH is of course approved according to the Federal Immission Control Act, is regularly inspected, certified and complies with all current environmental regulations.

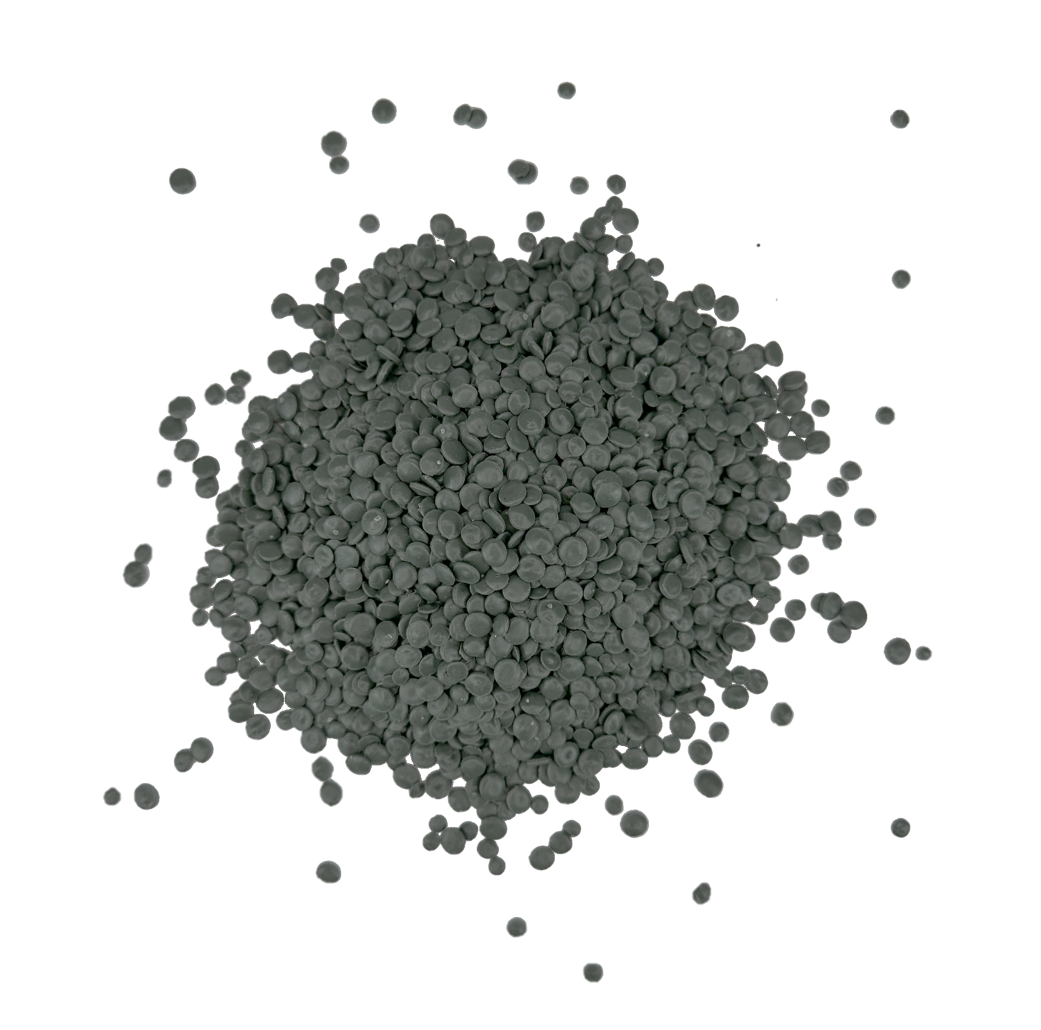

Systalen® rLDPE - recycling material for various applications

Systalen® recyclate granules are suitable for a wide range of applications, e. g. for injection molding, blow molding and extrusion.

In Eisfeld, we produce the following Systalen® LDPE recyclate grades:

- rLDPE 3.0 (odor-reduced)

- rLDPE 2.0 (finely filtered)

- rLDPE 1.0 (standard)

Depending on the application, the manufacturing process of a product and the requirements of our customers, we also offer customized formulations and can supply our Systalen® recyclate in various treatments, forms and compositions.

And different colors are of course no problem. After all, a green world must also be colorful.

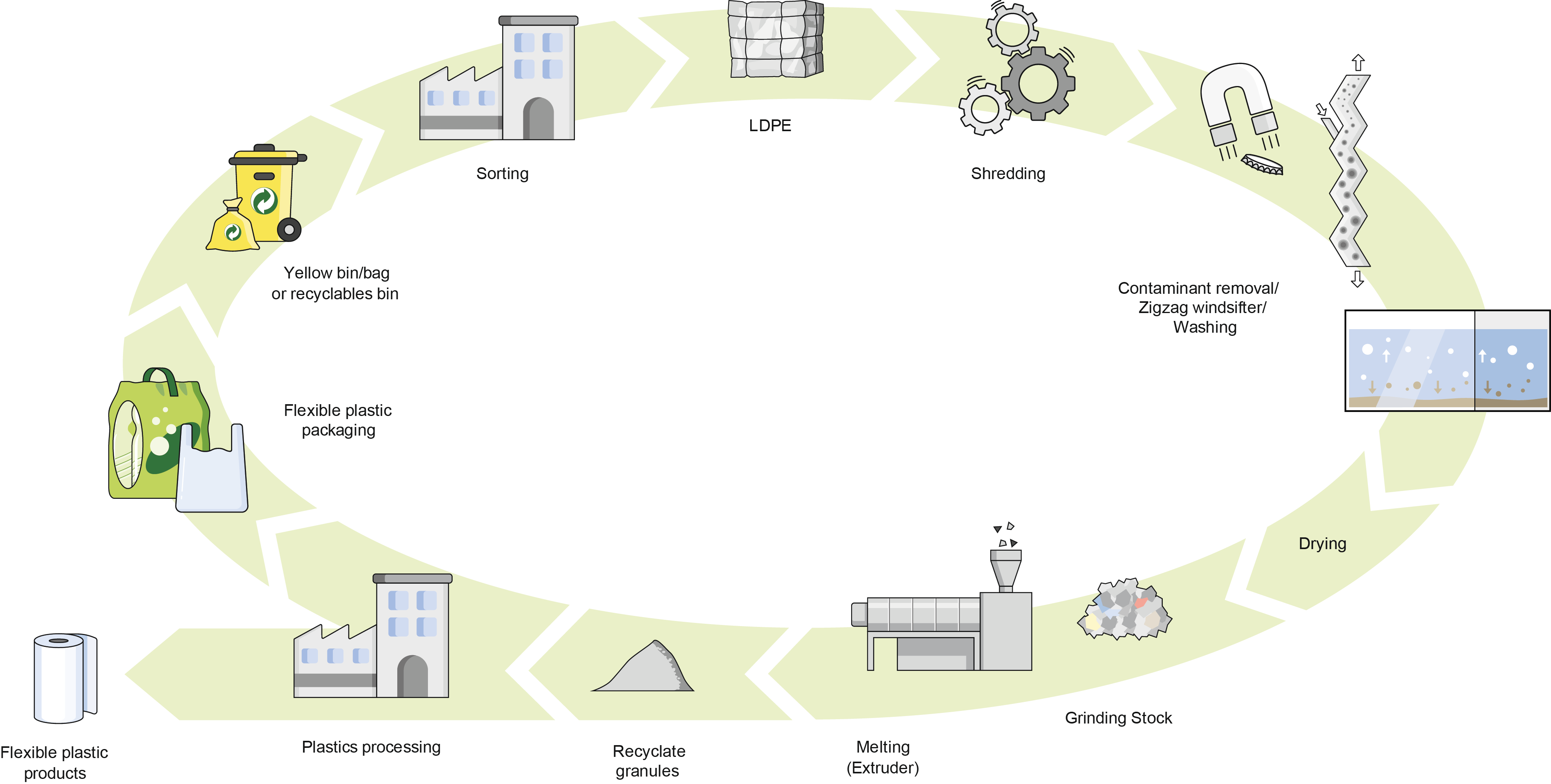

New packaging and products thanks to a closed loop

At Systec Plastics Eisfeld GmbH, Systalen® Low Density Polyethylene (LDPE) recyclates are produced whose origin is the yellow can or the yellow bag. These recycled granulates can then be used to produce new flexible plastic packaging, such as shrink films for beverage multi packs or plastic products like mailing bags, trash bags etc.

At Systec Plastics GmbH in Hörstel, on the other hand, Systalen® recyclates are manufactured from hard plastics (PP).

How do old packaging become new again?

Waste from household collection (yellow bin & yellow bag) is pre-sorted by material type in sorting facilities.

These pre-sorted LDPE bales are then first checked for quality and composition in our incoming inspection.

Then the bales are crushed and ferrous metals are separated at the same time.

In the next step, stones, rigid plastics, etc. are removed in the zigzag windsifter. Paper & organic materials are removed in dry mechanical cleaning.

Flakes are then cleaned in the float-sink basin and mechanical drying.

In extrusion, the regrind is finally melted, degassed, microfiltered and granulated.

The result is high-quality Systalen® recycled granules that are very suitable for further processing.

Each production batch is internally tested for various quality criteria such as flowability (MFI), color measurement, density, moisture, etc.

Further tests are possible on request, e.g. (DSC), (XRF), tensile test, near infrared (NIR).

Shipment and/or collection to/from customer after successful QA release.

Delivery/shipment according to customer's request by big bag, octabin or in silo truck.

We are always interested in committed, motivated and environmentally aware employees who enjoy working with and for people.

You can find our current vacancies here.

If we do not currently have a vacancy that fits your profile, we are also happy to receive .

Directions:

Systec Plastics Eisfeld GmbH

Am Eichgraben 10

Gewerbegebiet Süd

D-98673 Eisfeld

Telephone: +49 3686 39440

Telefax: +49 3686 394439

info-spe(at)gruener-punkt(dot)de

BY CAR

On highway A73 please take exit 6 'Eisfeld-Süd'. Drive approx. 2 km in the direction of Eisfeld. Then turn left into Gutsweg and drive approx. 1 km. Turn off the main road into Eichgraben. After approx. 300 m you will find the administration building on the left. Visitor parking is available there.