Many years of experience and continuous innovations make Systec Plastics GmbH in Hörstel the competence center for recycled granules and compounds made of polypropylene (PP) with

- two washing lines and

- two extrusion lines

The Systec Plastics plant in Hörstel is one of the largest European producers of post-consumer recyclates from yellow sacks and yellow garbage cans. The annual output is currently over 22,000 t of rPP.

The plant will be continuously expanded in the coming years.

Systec Plastics GmbH in Hörstel is of course approved according to the Federal Immission Control Act, is regularly inspected, certified and complies with all current environmental regulations.

Systalen® rPP - secondary raw material for many applications

Systalen® rPP granules are suitable for a wide range of applications, such as injection molding, extrusion and thermoforming.

In Hörstel, we produce the following Systalen® PP grades:

- rPP Standard

- rPP Extra

Depending on the application, the manufacturing process of a product and the requirements of our customers, we also offer customized formulations and can supply our recyclate in various treatments and compositions.

The Systalen® recyclates produced from household collection plastics are initially grey - but a wide range of colors can be achieved with the help of color batches.

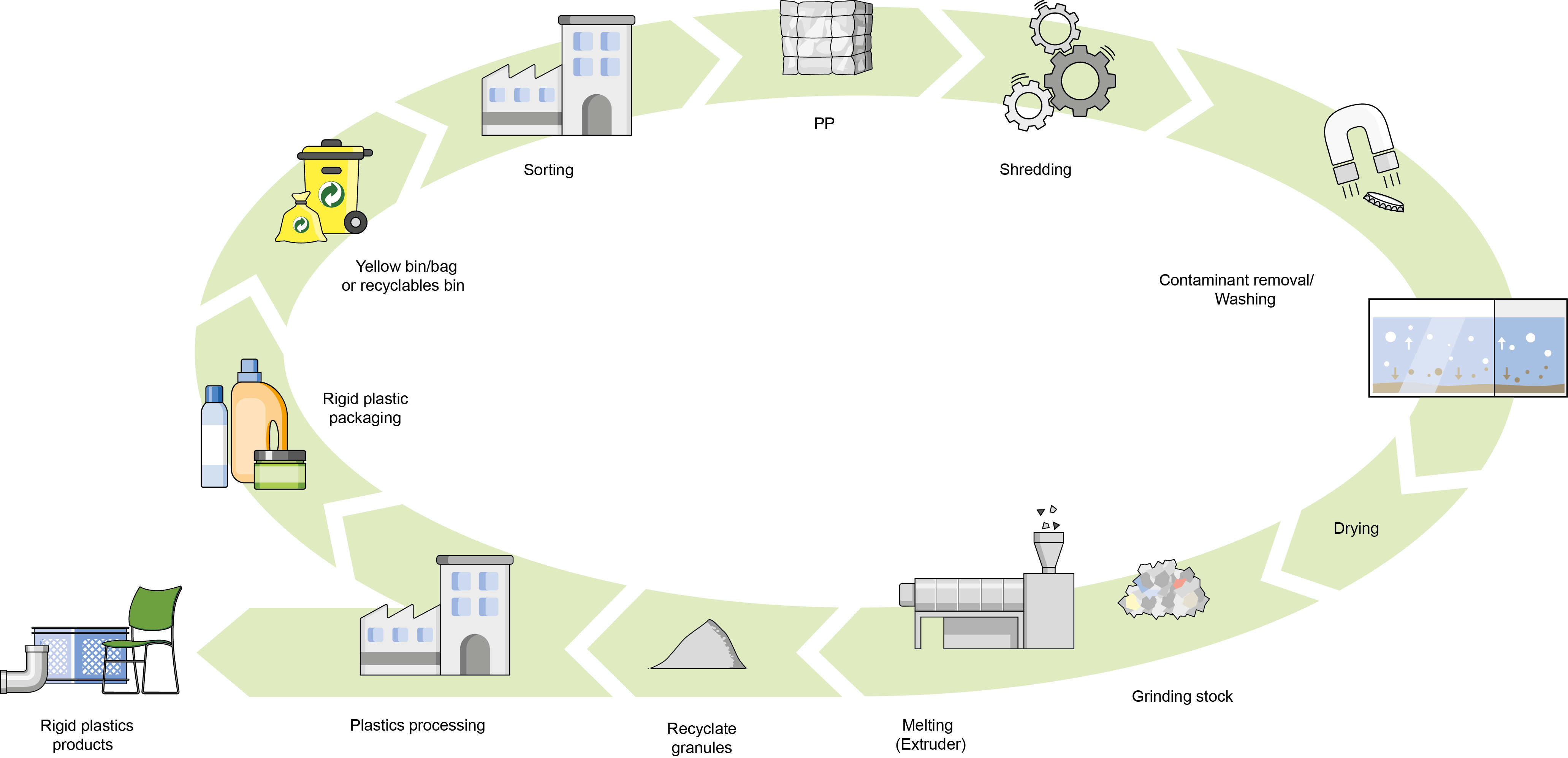

New packaging and production thanks to closed loop

At Systec Plastics GmbH in Hörstel, pure Systalen® recycled polypropylene (PP) granulate is produced from the waste from the yellow ton and the yellow bag. This can be used to produce new rigid plastic packaging such as closures, jars, etc. or rigid plastic products such as pens, chairs, boxes, baskets, flower pots, buckets & co.

Our Systec Plastics in Eisfeld produces Systalen® Low Density Polyethylene (LDPE) recyclates.

How do old packaging become new again?

Waste from household collection (yellow sack & yellow garbage can) is pre-sorted in sorting plants according to material type.

These pre-sorted PP bales are then first checked for quality and composition in our incoming inspection.

After quality inspection, the bales are shredded and ferrous metals are separated at the same time.

The plastic flakes then pass through several separation and washing stages.

In extrusion, the regrind is finally melted, degassed, microfiltered and granulated.

The result is high-quality Systalen® recycled granules that can be further processed very well.

Each production batch is regularly tested for various quality criteria. These include, for example, melt flow rate (MFI), color measurement on the granules, bulk density or volatile parts/moisture measurement.

In addition, further tests are possible on request, such as density, color measurements on the injection plate, DSC, X-ray fluorescence (XRF), tensile test (23°C), notched impact strength (23°C) or ash & carbon black content.

Dispatch and/or delivery from/to customer after successful QA-approval.

Shipment according as requested by the customer by big bag, octabin or in a silo truck.

Jobs & careers at Systec Plastics GmbH in Hörstel:

We are always looking for committed, motivated and environmentally interested employees who enjoy working with and for people.

You can find our current vacancies here.

If we do not currently have a vacancy that fits your profile, we are also happy to receive unsolicited applications.

Get there:

Systec Plastics GmbH

Röntgenstraße 6

D-48477 Hörstel / Germany

Telefon: +49 5459 80230

Telefax: +49 5459 8023101

info-sp(at)gruener-punkt(dot)de

BY CAR

On the BAB 30, take exit 10 'Hörstel' and drive on Bergeshöveder Str. towards Hörstel. Leave the next roundabout at the second exit to stay on Bergeshöveder Str.. After approx. 1km you will come to a crossroads where you turn right onto Ibbenbürener Str. After another approx. 800m turn left into Dornierstr. Follow this road for 700m, where you turn left into Röntgenstr. After 300m you will find Systec Plastics on the right-hand side. Visitors are welcome to use the parking spaces available on the right side.