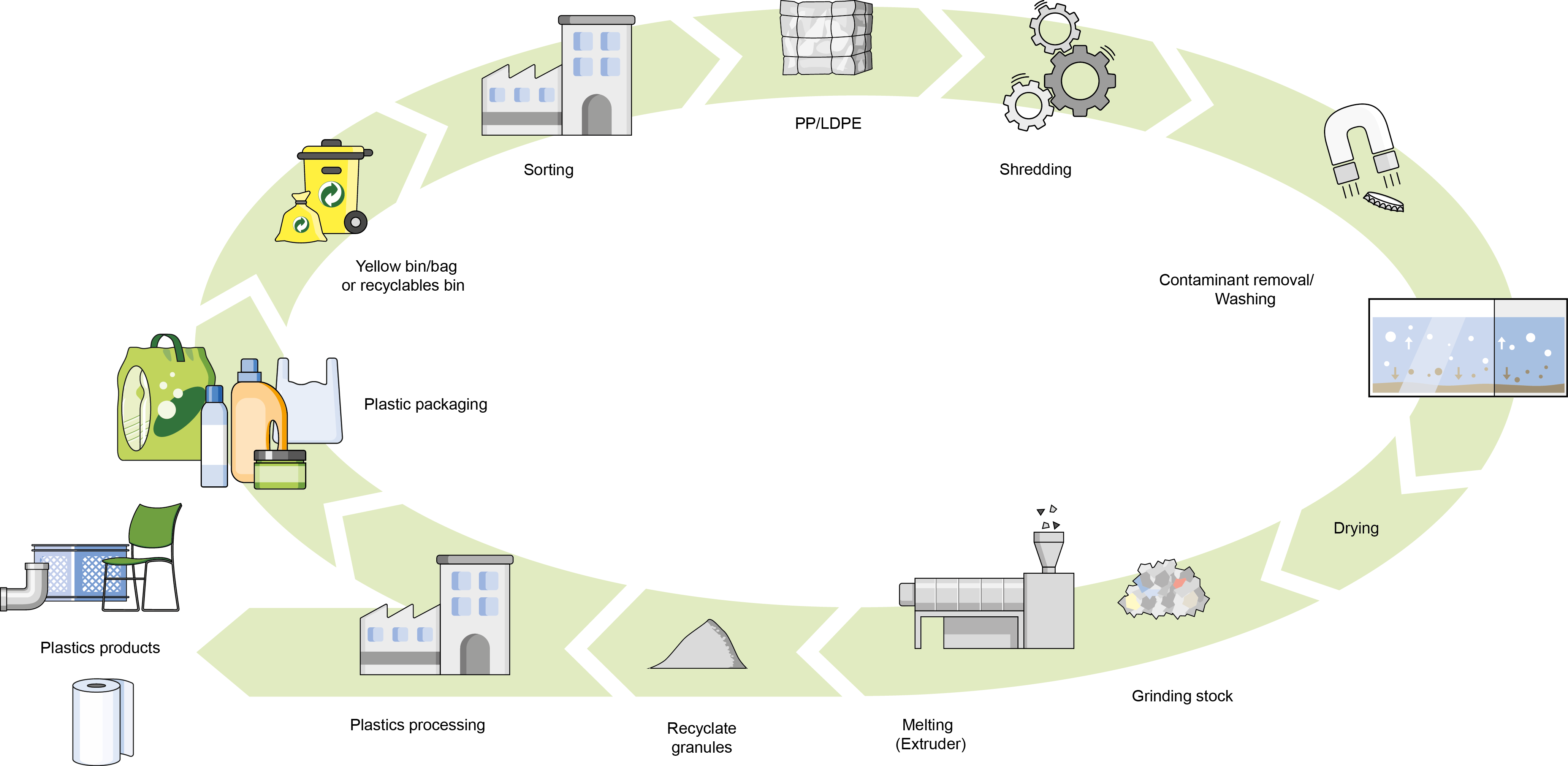

Post Consumer Recyclate (PCR) from household collection

The starting material for post-consumer recyclate (PCR) and thus also our Systalen® recyclate is waste from household collection (yellow bag & yellow bin) in Germany. These are first pre-sorted in sorting facilities.

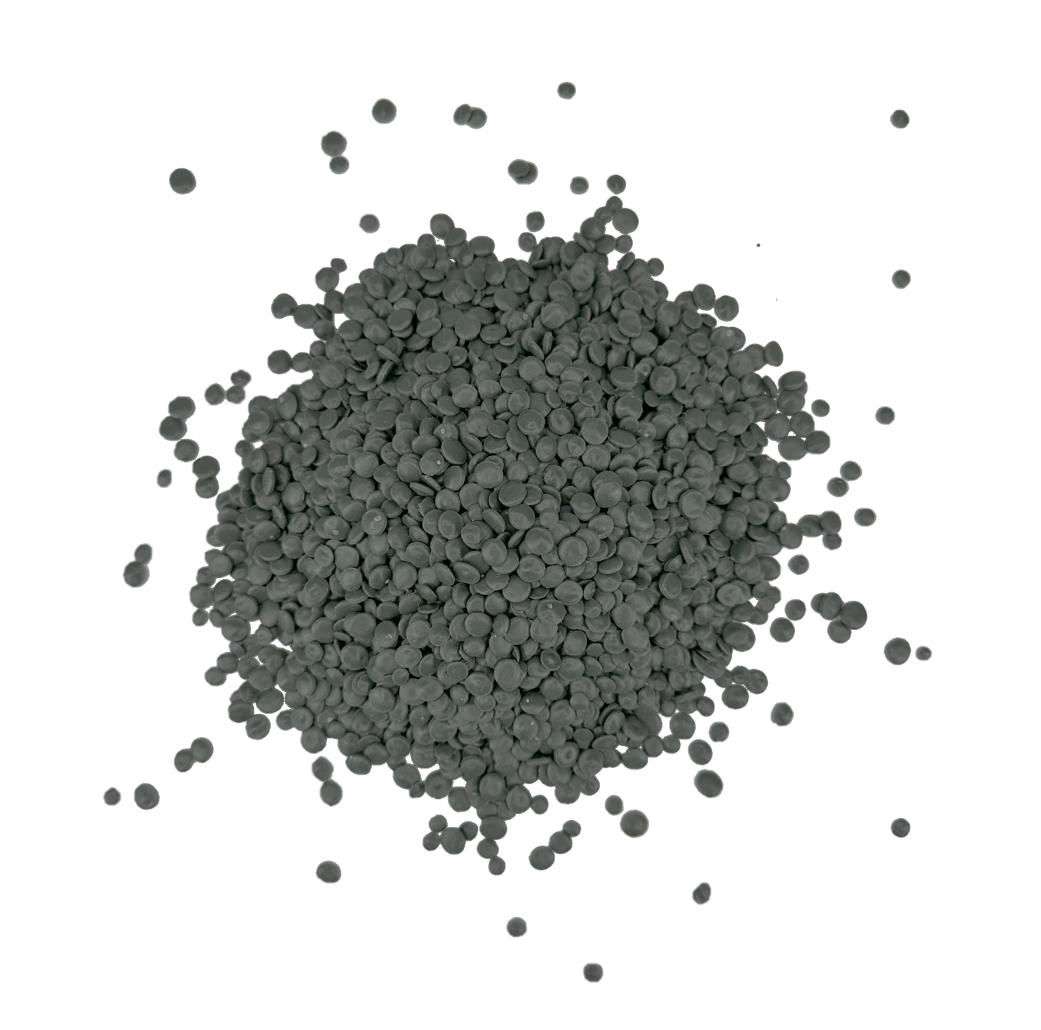

Mono-fraction bales of recyclable materials delivered to us are then the starting material for our Systalen® recyclate. After the incoming quality inspection, several shredding, separating and washing stages follow. The shredded and washed plastic flakes are then melted, degassed, microfiltered and finally granulated. This results in high-quality Systalen® PCR granules which are optimally suited to be used in new packaging or products.

Polypropylene (PP)

- for injection molding, extrusion and thermoforming

Low-Density Polyethylen (LDPE)

- for injection molding, blow molding and extrusion

New packaging and products thanks to closed-loop recycling

Systalen® PP recyclates can be used, for example, to produce new rigid plastic packaging such as caps, jars & co. or rigid plastic products such as pens, chairs, boxes, baskets, flower pots, buckets etc. Systalen® LDPE is a sustainable secondary raw material for high-quality flexible plastic products and packaging, such as shrink films for beverage bottle containers or shipping bags, trash bags, etc.

We support our clients & projects throughout the entire development process

Our well-coordinated team of experienced technicians, engineers and developers, who know what matters in every production, and our competent sales team are always there to answer your questions and form the bridge to our production sites.

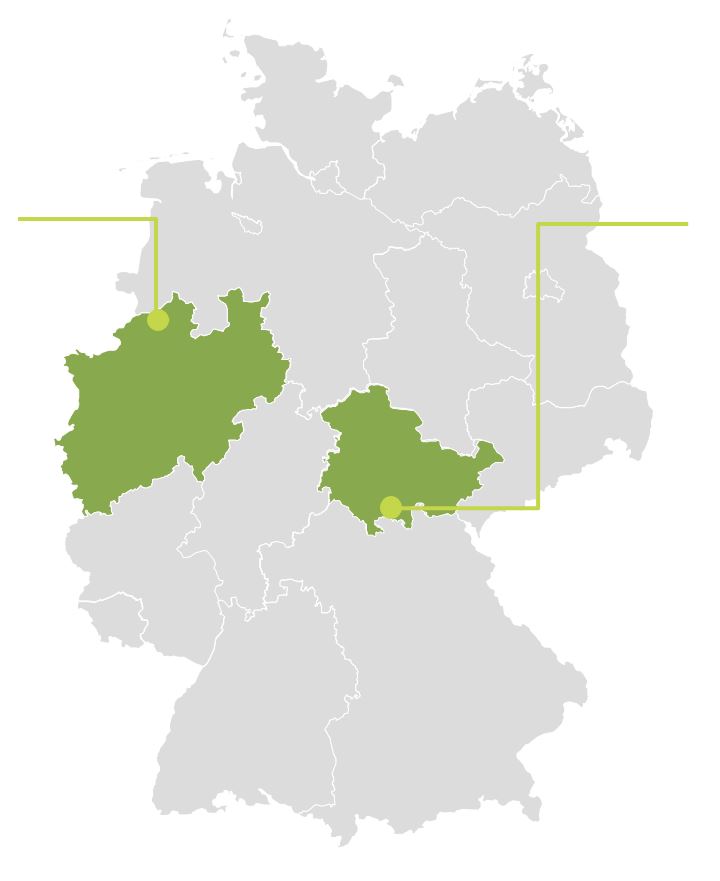

Systalen® - Produced in our competence centers for plastics recyclates

As the so called 'mother of all EPR systems', Der Grüne Punkt has always set standards in closing the recycling loop and using raw materials from post-consumer collections. The company's own customized production and continuous development of plastic recyclates under the Systalen® brand therefore underlines the innovative spirit and foresight of the corporate group. The high-quality post consumer recyclates are manufactured in our two Systec Plastics plants in Germany.

Systec Plastics in Hörstel

Spezialized in the recycling of rigid plastics (PP), the Systec Plastics plant in Hörstel is equipped with

- state-of-the-art recycling plant technology,

- two washing lines and

- two extrusion lines

Systec Plastics Eisfeld

As competence center for the recycling of flexible plastics (LDPE), Systec Plastics Eisfeld has

the latest technology for recycling flexibles,

seven washing and three extrusion lines and

one of Europe's largest exhaust air bio-filter plants (filter size > 1,000 m²)

Both plants are, of course, licensed in accordance with the Federal Immission Control Act, are regularly inspected and certified, and meet all current environmental requirements.

Our production sites have their own test laboratories equipped with state-of-the-art laboratory technology, for measuring all relevant mechanical and physical properties of our Systalen® recyclates.

These offer the possibility of customized solutions and individual customer requirements while ensuring the quality of our products.

Thanks to our in-house testing laboratories, many tests are included with every batch. These include flowability (MFI), color measurements on the granules, density, bulk density or volatile matter/moisture measurement.

Further, internal analyses are available on request, such as color measurements on the splash plate, DSC, XRF (X-ray fluorescence), tensile test (23° C), notched impact strength (23° C) and ash & carbon black content.

For each production batch and delivery, the analyses agreed in the customer specification are carried out. The provision of the test values takes place via a test certificate, if desired, which will be sent to you by your preferred method. All tests are performed with our state-of-the-art laboratory equipment and according to test standards.

Due to our long-term partnership with an accredited testing institute, we offer our customers customized batch-related regulatory analyses. We are happy to commission analyses in accordance with REACh Regulation (EC) No. 1907/2007, RoHS 2011/65/EU, Blue Angel DE-UZ 30a (only for PP) or analyses in accordance with the toy standard DIN EN 71-3.

We will be pleased to confirm compliance with the standards and regulations via our legally binding declaration of conformity. Please contact us!

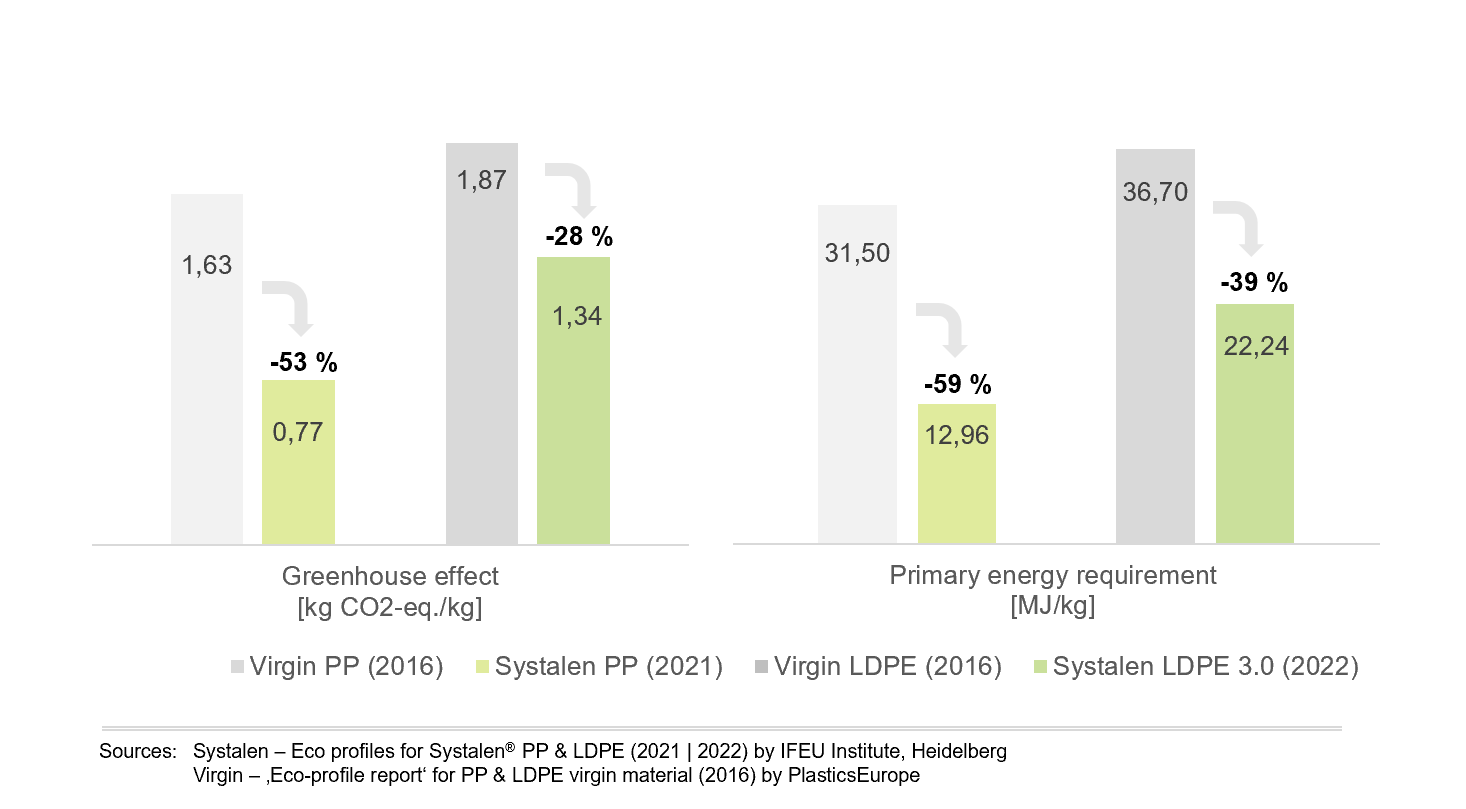

Convincing advantages when replacing virgin plastic with recycled plastic

Systalen® recycled granules are produced from used plastics and not from virgin crude oil like other granules. In addition, the manufacturing process also saves energy for the production process and reduces CO2 emissions. Systalen® recyclates thus measurably conserve the environment and resources in a sustainable manner.

The eco-profiles of the IFEU Institute in Heidelberg make it possible, among other things, to precisely quantify and certify the CO2 savings when using Systalen® recyclate compared to virgin material and thus the contribution to sustainability.

For further information and details of our eco-profiles, please do not hesitate to contact us.

Closing the loop is increasingly moving from 'nice-to-have' to 'must-have'.

Social, tax and political pressure to use recycled plastics is increasing.

The demand and need for plastic recyclates is growing faster than the supply.