We want to get better and better. So communicating with our stakeholders plays a special role. An exceptionally large number of groups are relevant to our work. We identified the most important of them back in 2015 using a comprehensive stakeholder analysis. We have updated the list, but have not determined any material changes for this latest report.

Key Topics

Based on conversations with our stakeholders, we know which topics we should drive forward as a matter of priority. The issues that we want to focus on reflect our unique business model where policy-making, business, and society meet. As a result, and as a further evolution of our materiality matrix, we have come up with nine equal areas of action – each with several key topics and a link to specific Sustainable Development Goals (SDGs).

Waste hierarchy becoming more important

How should we deal with waste? This is a key issue facing our industry. The European Waste Framework Directive sets out a clear hierarchy. Recycling takes third place in this hierarchy after waste prevention and reuse. Energy recovery and disposal operations only then follow in fourth and fifth place. For us, value creation stretches from manufacturing to recovery. Since 2007, we have been advising our customers on how to design their packaging to be as recycling-friendly as possible. Demand for this service has soared, due in part to strong political pressure on manufacturers to take action (you can find more on this in the Market section). Research, advisory services, and making recycled materials – three areas that are closely intertwined – are therefore the areas of the future for Der Grüne Punkt.

FLAGSHIP PROJECT:

A blue coat, but green to the core

Automatic sorting systems have so far failed to recognize black plastic flowerpots. Pöppelmann – a German manufacturer of plastic injection molded and thermoformed items – is forging a new path. In summer 2017, the plastic specialist became the first company in the world to develop thermoformed flowerpots that are proven to fully close the raw material loop as part of its company-wide PÖPPELMANN blue® initiative. These Pöppelmann TEKU® flowerpots are made out of our resource-friendly Systalen PRIMUS PP and have been certified as 100 percent recyclable by the cyclos-HTP institute. Our Design4Recycling advisory services meant that flowerpots could be designed in a way that allows their material to be easily identified by near-infrared sorting technology. The RAL Quality Mark for Recycled Plastic shows the packaging’s content of plastic from the yellow bin or yellow bag. As part of PÖPPELMANN blue®, the company is currently working in close partnership with Der Grüne Punkt to develop additional closed-loop products made by Pöppelmann.

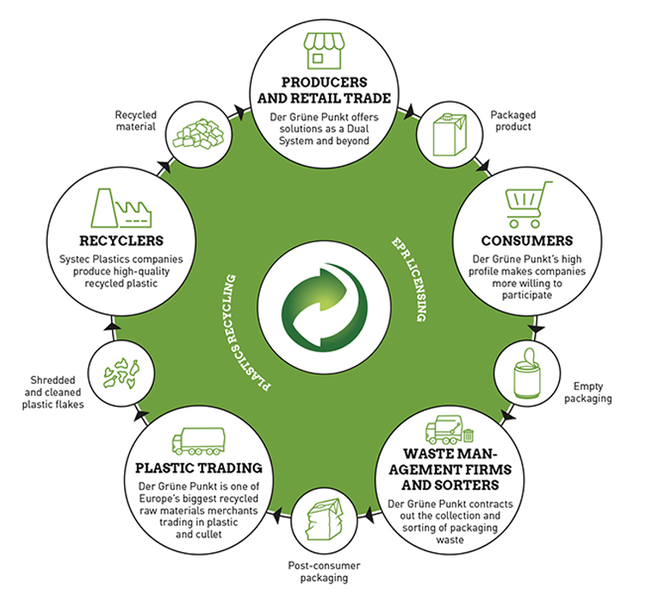

Value cration is complex

Packaging has to be functional, easy to handle, and also efficient to manufacture. Our Design4Recycling approach helps manufacturers design their packaging to be recyclable. Post-consumer packaging can only be sorted and recycled if consumers discard it properly. We have set standards that our partners – from local collectors to sorters and the recycling plant – uphold when handling different recyclables.