Plastics recycling in Germany has huge development potential. A fully functional market for recyclates is already in place. The dual system has made a crucial contribution here, and in addition purposefully expanded its economic benefi ts. The situational conditions will play a vital role in further developments.

Applications and demand for premium recyclates are steadily increasing. Capital investment is essential for sustainedly tapping this market. There is still, however, a lack of incentives. Higher quotas and improvements in enforcement would contribute towards utilizing the huge economic potentials of plastics recycling by the dual system to even better effect, as would giving more weight to ecological factors in fixing the participation fees, or extending product responsibility to non-packages made of the same materials.

Status Quo

The market volume for recycled products made from post-consumer lightweight packages (plastic, aluminum, tinplate) nowadays comes to approximately 315 million euros. In particular, technical advances and the improved quality of recyclates were crucial in developing this market. The dual system has made a vital contribution to this. The major drivers behind this success story include the statutory quotas for material recycling laid down in the German Packaging Ordinance, opening up the dual system to competition, and the continuously rising level of acceptance for recycled products among companies and consumers.

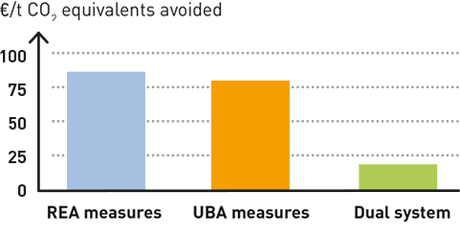

The total economic benefits achieved by the dual system, nowadays amounting to approx. 960 million euros, can be set against annual system costs of about 775 million euros, producing net benefits of 185 million euros. The dual system’s economic benefits have increased over the course of time, while the system’s costs, thanks to innovations and competition, have been substantially downsized. The dual system’s CO2 avoidance costs are nowadays running at 17 euros per ton of CO2 saved, which is significantly lower than is the case with correspondingly targeted climate protection measures for increasing the use of regenerative energy – e.g. less than a fifth of the CO2 avoidance costs entailed by regenerative energy sources on average under the Renewable Energies Act (REA). In a comparative study, the German Federal Environmental Agency (UBA) determined in 2014 average costs of 77 euros per ton of CO2 saved.

Investments are frequently rejected as a viable option under the current situational conditions, but would be necessary in order to utilize to the full the dual system’s available potentials in terms of collection, sorting, and recovery, and to open up a genuine market for premium recyclates. Moreover, there are still disincentives in place in fixing the participation fees that lead to reduced recyclability of packaging and lower quality of the input material for recycling.

Outlook

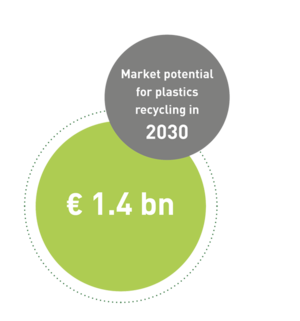

If existing potentials in collection, sorting, and recovery are harnessed, if non-packages made of the same materials are collected together with packaging, and a market for premium recyclates is created, then the market for plastic recyclates can by 2030 grow from its present-day 189 million euros to as much as 1.4 billion euros.

By harnessing the currently existent potentials (optimizing collection, sorting, and recovery, including non-packages made of the same materials, and higher quota stipulations), the annual economic benefits of the dual system could be significantly upsized from the present-day figure of 960 million euros to 1.3 billion euros. Admittedly, implementing these measures would entail costs but the net benefits of the dual system would nonetheless be substantially increased.

Companies are attaching progressively more importance to their ecological image. In their decision-making, corporate social responsibility and instruments like product life-cycle analyses are gaining in perceived importance. New market fields for recyclates are opening up, particularly when the quality and availability of secondary raw materials are being further enhanced.

Background

More recycling! This formula is seen as a crucial step forward on the path leading to a more sustainable economy and society. In view of climate change, environmental pollution, population growth, and resource dependence, the closing of cycles is for many people not only an ecological imperative, but at the same time a crucial instrument for shaping the economy to meet and master the tasks of the future. This applies particularly to plastics, as a complex and comparatively young material, whose recovery involves special challenges and opportunities.

In the field of package recycling, Germany is one of the most important front-runners. In 1990, the legislature introduced product responsibility, and thus put in place the foundations for the first dual system tasked with the collection and recovery of packaging waste – Der Grüne Punkt GmbH. This was also a milestone on the path to closed material cycles, which nowadays constitute a role model for many countries inside and outside Europe. After being opened up to competition, the dual system in Germany comprises eleven system operators, and the Green Dot is used well beyond the country’s borders. It is acknowledged as one of the best-known trademarks around, seen as a symbol for eco-awareness and resource-economy.

A VIEW INTO THE FUTURE OF THE DUAL SYSTEM

But how can more plastics recycling be achieved? Where do its greatest potentials lie, and how can they be tapped? What role does the dual system play in this context? And what obstacles have to be overcome in order to close the cycles to better effect?

These questions have so far been posed, discussed, and examined predominantly from an ecological perspective. Technological aspects, too, such as design enhancement of separation and sorting technology, have so far not been tackled systematically in regard to their future potential for the closed-cycle economy. With a study entitled “Economic outlook for plastics recycling – the dual system’s role,” the RWI – Leibniz Institute For Economic Research, on behalf of DSD – Duales System Holding GmbH & Co. KG, has now examined these questions from an economic perspective. In this study, verified by an independent appraiser, the RWI also takes a look into the future. What is being signposted by ongoing developments and market trends? Under what conditions can the use of secondary raw materials made from post-consumer lightweight packages be expanded? How will the market develop? This study thus makes an important contribution towards the discussion on effective paths to a closed-cycle economy.

Today, the closed-cycle economy in Germany already subsumes more than 10,000 companies with over 250,000 employees.* Nonetheless, the transition from a linear to a closed-cycle economy is without a doubt still in its early stages. Flagship projects are indeed demonstrating with increasing effect that complex packages consisting largely or completely of recyclate can prosper on the market, but these examples continue to require out-of-the-ordinary initiative from individual protagonists, most of them from the private sector. And even though the quality and quantity of secondary raw materials have made great advances in recent years, major challenges still remain in terms of scaling these solutions.

* BDE, ITAD, VDMA (2016): „Branchenbild der deutschen Kreislaufwirtschaft“ (Structure of the German closed-cycle-economy sector)

Approach and methodology

The RWI bases its findings on the figures provided in the most recent study from the Institute of Applied Ecology* on the ecological achievements and potentials of the dual system. The RWI analyses the data available using econometrically based forecasting procedures and utilizes interviews with experts along the value added chain so as to estimate the effects of ongoing technological developments and market trends.

In its study, the RWI adapts its methodology and approach to suit the key questions and the availability of the quantitative variables. Interviews with experts were used to draw up a picture of the latest advances, and their effects on the further development of plastics recycling. In all, the insights gained from more than 20 interviews with experts along the value added chain were incorporated (including: dual systems, recycling companies, sorting plant operators, first-time distributors). The exploration of future development scenarios for the dual system is based upon econometrically validated forecasts, such as Monte Carlo simulations. The study focuses on the lightweight packages made of plastic collected by the dual system. But other material fractions from the Yellow Bin are also covered, like aluminum and tinplate.

* Öko-Institut – Institute of Applied Ecology (2016): “Recycling is the future – ecological achievements and potential of the dual system”, www-gruener-punkt.de/oeko-studie.